We look forward to being your best partner or E-mail us at

sales@china-cfc.ccThe granite structure is uniform, the texture is hard, the color is beautiful, and it is durable. It is a high-quality building stone and is known as the "king of rock". Granite can be used from roof to floor in buildings.

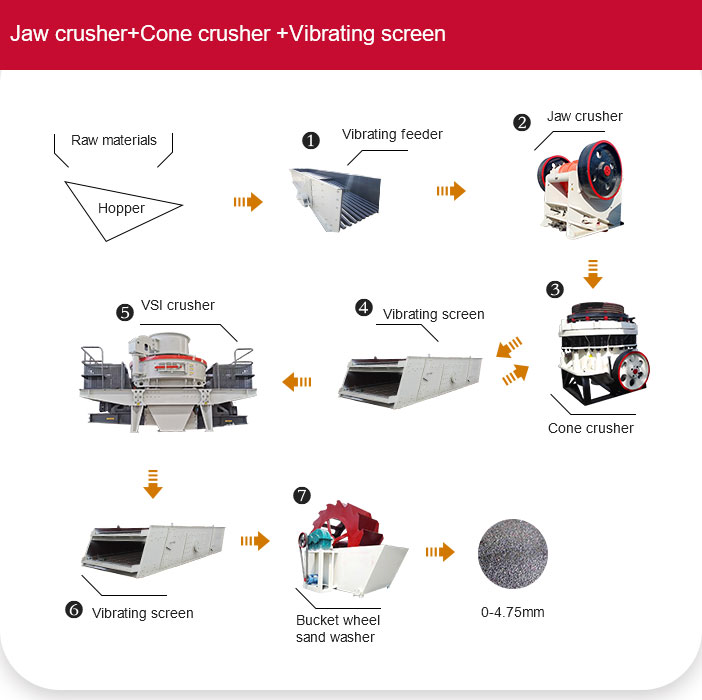

The processing of granite is divided into four stages: coarse crushing of jaw crusher, medium crushing of impact crusher or cone crusher, and sand making and packaging of sand making machine.

The first stage: coarse crush

Granite bulk material is uniformly fed by the vibrating feeder through the silo, and conveyed to the jaw crusher for coarse crushing. After the coarsely crushed material is sieved by the vibrating screen, it is transported by the belt conveyor to the impact crusher or cone. The crusher is finely crushed.

The second stage: medium and fine

After the granite that has been transported to the counter-breaking/cone break is finely crushed, it is sieved by a circular vibrating sieve, and the larger granular material is returned to the counter-breaking/cone breaking and broken again.

The third stage: sand making

The crushed granite is sent to the sand making machine for further crushing and shaping. If it needs clean granite, it can be sent to the sand washing machine for cleaning.

The fourth stage: packaging

The finished product after drying is packaged and stored.