We look forward to being your best partner or E-mail us at

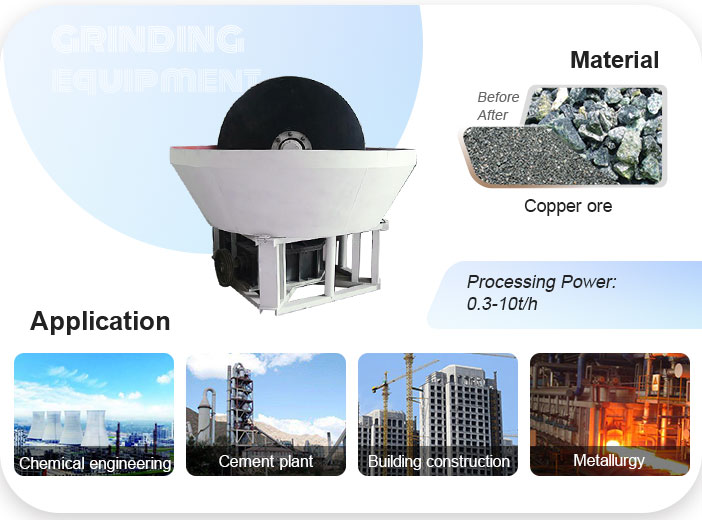

sales@china-cfc.ccWet Pan Mill also known as the gold grinder mill, is widely used in the medium or small size of mineral processing. With low investment and high output, the wet pan mill is normally used for separating gold, iron, molybdenum, lead, zinc, antimony, and so on.

The motor firstly drives the decelerator, then the central drive shaft transfers the horizontal shaft to move the roller with the anticlockwise direction, so that the material in the wet pan mill is ground into fine particles. The roller mixes the material and water thoroughly inside of the wet pan mill, and the fine particles will float to the upper surface, which can be discharged through the overflow discharge port. The coarse-grained minerals will settle at the bottom and will be continuously ground into small fines that reaches the standard.

| Model | Feeding size(mm) | Output size (mm) | Capacity (t/h) | Motor power (kw) | Weight (t) |

|---|---|---|---|---|---|

| 900 | <15mm | 0.6-0.07 | 0.1-0.4 | 3 | 3.2 |

| 1000 | <20mm | 0.6-0.07 | 0.5-0.8 | 5.5 | 4.8 |

| 1200 | <20mm | 0.6-0.07 | 0.5-1.2 | 7.5 | 6.2 |

| 1400 | <20mm | 0.6-0.07 | 1-3 | 18.5 | 9.5 |

| 1500 | <30mm | 0.6-0.07 | 2-5 | 22 | 12.5 |

| 1600 | <30mm | 0.6-0.07 | 4-6 | 30/37 | 16.2 |

Note: The capacity may vary with different materials and feeding sizes.