We look forward to being your best partner or E-mail us at

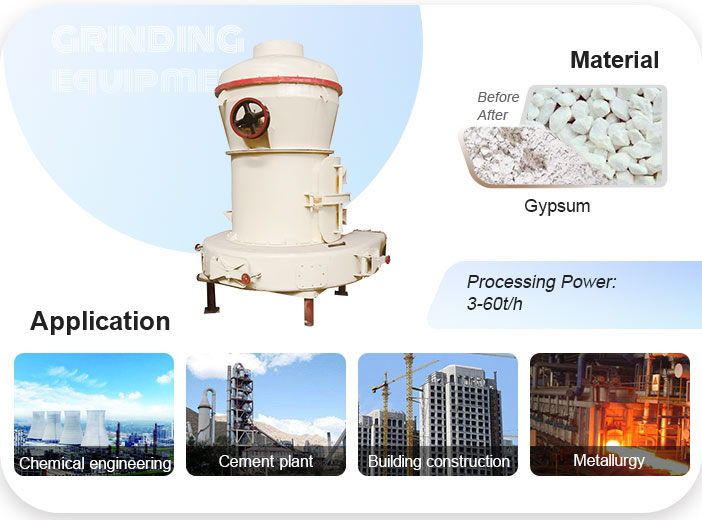

sales@china-cfc.ccMTW European trapezoid mill adopts a number of the latest patented technologies such as bevel gear integral drive, internal oil lubrication system, arc air duct, etc. At present, this mill has been used in metallurgy, electric power, chemical industry, steel, building materials, coal and other industries. It is mainly used for grinding various non-flammable and explosive mineral materials with Mohs hardness below 9.3 and humidity below 6%, with features of big feeding size of 25-35mm and wide rang production capacity of 3-22 TPH.

The system consists of grinding mill, separator, air blower, jaw crusher, vibrating feeder, hopper, dust collector, pipe, powder collector, electric cabinet, motors, etc. Big lump materials are crushed to required size by jaw crusher, then elevated to buffering hopper through elevator, after that fed into the mill to be ground. Materials are to be ground between ring and rollers, and move up with the air flow, those particles which cannot pass the separator will fall down and be ground again, while others will be collected as finished product. Air flow passing through separator will go to the air blower for recycling, it's a closed system.

| Model | MTW110 | MTW138 | MTW175 | MTW215 |

|---|---|---|---|---|

| Max. Feed Size(mm) | <30 | <35 | <40 | <50 |

| Output fineness(mm) | 1.6-0.045, fineness 0.038 |

1.6-0.045, fineness 0.038 |

1.6-0.045, fineness 0.038 |

1.6-0.045, fineness 0.038 |

| Capacity(t/h) | 3-9 | 6-17 | 9.5-25 | 15-45 |

| Main motor(kW) | 55 | 90 | 160 | 280 |

| Fan motor(kW) | 55 | 110 | 200 | 315 |

| Main shaft speed (rpm) | 980 | 990 | 740 | 740 |

Note: The capacity may vary with different materials and feeding sizes.