We look forward to being your best partner or E-mail us at

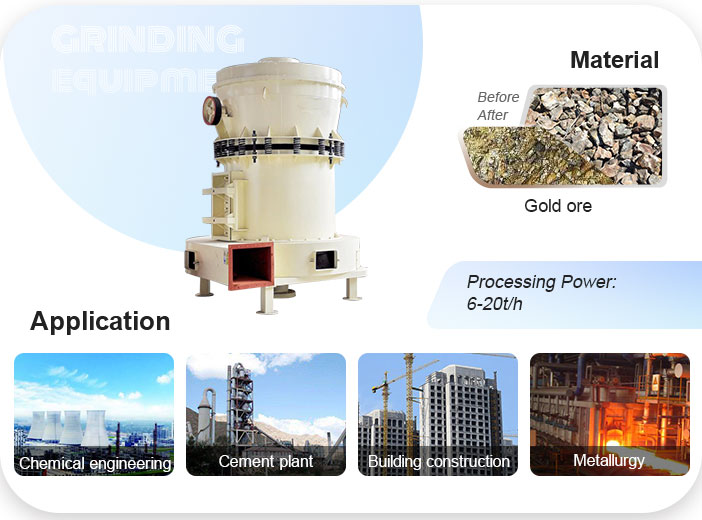

sales@china-cfc.ccHyper-pressure trapezoid mill is widely used in electric power, mining, metallurgy, chemical industry, steel, building materials, coal and other industries, with Mohs hardness below 9.3 and humidity below 6% of various non-flammable and explosive mineral materials, finished products Fineness can be adjusted arbitrarily between 30-400 mesh, such as cement (raw clinker), quartz, feldspar, calcite, dolomite, graphite, fluorite, wollastonite, phosphate rock, calcium magnesium phosphate fertilizer, coal, coal gangue , slag, zircon sand, talc, granite, potassium feldspar, marble, barite, ceramics, glass and other more than 1,000 kinds of materials grinding and processing.

Large materials are crushed by Jaw crusher to the needed sizes firstly, then the materials are elevated to storage hopper by bucket elevator, third, the materials are fed into the grinding chamber for grinding by vibrating feeder equably and continuously. The powder after grinding goes upwards together with the airflow, after separating by powder separator, those which can meet the fineness requirement enters into the cyclone powder collector through pipe together with the airflow, and then discharged from the discharge valve as final products. The airflow is sucked into centrifugal blower through wind recycling pipe at the upper part of cyclone powder collector. The mainframe is driven by the speed reducer through the central axis in the mill. The quincunx stand connected with the upper part of central axis, at the quincunx stand, rollers are set and by which the vibrating pivot formed. Below the quincunx stand and rollers there is shovel system. Materials are fed into the space between rollers and shovels when they are turning, and then be grinded by the pressure produced when rollers are turning, thus powder is made.

| Model | HYTM100 | HYTM130 | HYTM160 | HYTM130X |

|---|---|---|---|---|

| Max. Feed Size(mm) | <25 | <30 | <35 | <30 |

| Output fineness(mm) | 1.6-0.045, fineness 0.038 |

1.6-0.045, fineness 0.038 |

1.6-0.045, fineness 0.038 |

0.074-0.045, fineness 0.038 |

| Capacity(t/h) | 3-3.8 | 6-13 | 13-22 | 4-13 |

| Main motor(kW) | 37 | 75 | 132 | 75 |

| Fan motor(kW) | 37 | 75 | 132 | 75 |

| Main shaft speed (rpm) | 1480 | 1480 | 1480 | 1480 |

Note: The capacity may vary with different materials and feeding sizes.