We look forward to being your best partner or E-mail us at

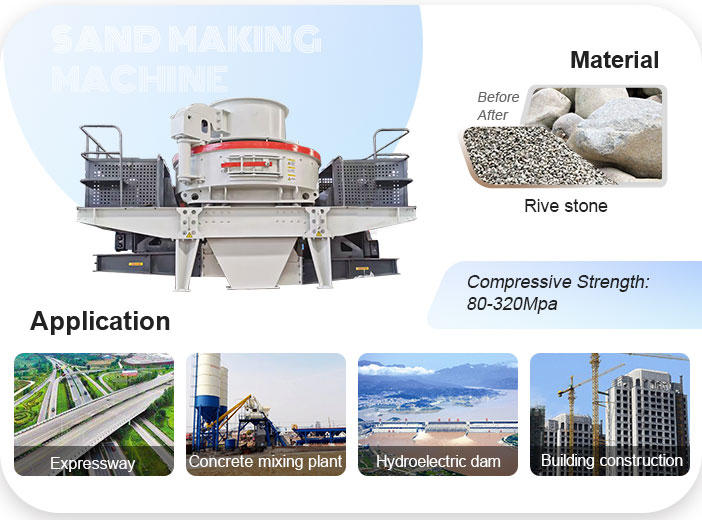

sales@china-cfc.ccVertical shaft impact crusher is widely used in crushing and reshaping of rock and artificial sand making. It is suitable for crushing of fragile materials below level 9 of Moh’s hardness rather than viscous materials or stone materials containing much solid.

The raw materials are fed into the vertical shaft impact crusher by the feeding machine. The materials heap upon the scattering disc, and fall to the distribution disc from the rim of scattering disc. The materials are divided into two parts. One part falls into the high-speed centrifugal plate from the feeding pipe at the center of distribution disc. This part of materials is given high rotating speed and flung out through the runner of centrifugal plate. Firstly, the flying materials collide with the other part of materials which fall down from the rim of distribution disc, and then all the materials impact the lining of crushing cavity. As mentioned above, the materials will be impacted, rubbed and grinded repeatedly until fall out of the crushing cavity and into the discharge hopper.

| Model | Capacity | feeding size | Power ofdouble motor(kW) | Weight(t) | Voltage(v) |

|---|---|---|---|---|---|

| VSI-7611 | 60-120 | 35 | 110 | 11.8 | 380V |

| VSI-8518 | 100-260 | 40 | 180 | 14.5 | 380V |

| VSI-9526 | 150-380 | 45 | 264 | 17.8 | 380V |

| VSI-1140 | 225-520 | 50 | 400 | 25.6 | 380V |

Note: The capacity may vary with different materials and feeding sizes.