We look forward to being your best partner or E-mail us at

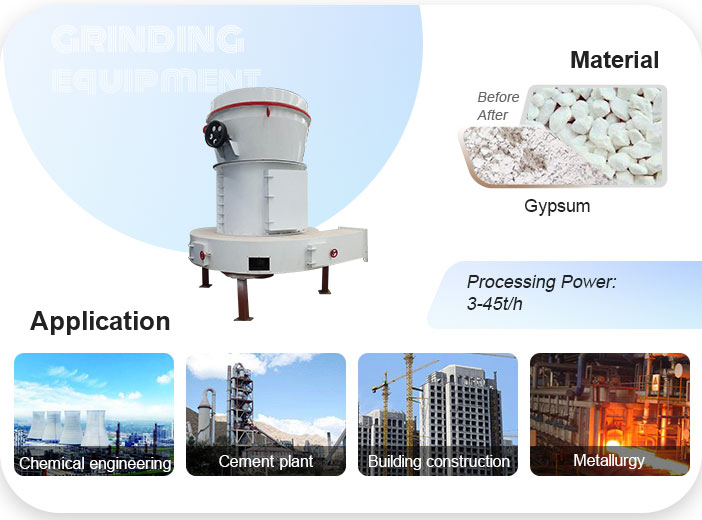

sales@china-cfc.ccRaymond Mill is suitable for grinding of all kinds of materials whose Moh’s hardness is below 9.3, such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, clay, white mud, mica, refractory material, glass, total about 1000 kinds of materials.

After the materials enter the grinding chamber of the main frame, the grinding roller swings outward and presses closely upon the grinding ring due to the centrifugal force generated by the rotation of the main shaft. The blade carries materials to the space between the grinding roller and grinding ring, and materials are ground as the grinding roller rolls. After being ground, the powder is selected by classifier via the cycle wind of the blower and the rough powder will be back to the grinding chamber for regrinding. The qualified powder is brought into the powder collector together with airflow. The powder comes out as end products while the airflow goes back to the powder collector in cycling to make the machine work normally. The remained airflow comes out after purification by dust filter.

| Model | FeedingSize(mm) | FinishedSize(mm) | Capacity(t/h) |

|---|---|---|---|

| YGM7815 | 15 | 0.613-0.033 | 1--3 |

| YGM8314 | 20 | 0.613-0.033 | 1.2-4.6 |

| YGM9517 | 25 | 0.613-0.033 | 2.1-5.6 |

| YGM4121 | 30 | 0.613-0.033 | 2.8-10.5 |

| HYM1600 | 35 | 0.613-0.033 | 5--50 |

Note: The capacity may vary with different materials and feeding sizes.